In mid-may 2022, the atmospheric and vacuum distillation unit of Shenghong refinery started up successfully, increasing the refining capacity of east China by 16 million tons per year. South China in 2022 has a large-scale refinery integration project production plan, other planning projects are also speeding up, the domestic refinery integration layout is basically finalized.

May 16,2022 according to a statement issued by Jiangsu Dongfang Shenghong Co. , Ltd. , the 16-million-ton refinery-chemical integration project of Shenghong Lianyungang Co. , Ltd. is now ready for commissioning, the atmospheric and vacuum distillation unit of Shenghong refinery was successfully started up at one time. Atmospheric and vacuum distillation unit start, means that refining and chemical industry chain through will also settle the dust. 16 million tons per year of oil refining projects put into production, in the large-scale domestic refining and chemical integration projects to add a heavy color.

01、“Refining” to“Refining”, the future development of the petrochemical industry is an inevitable trend

Shenghong Refining & Chemical Co. , Ltd. has built the integrated pattern of the whole industry chain of“Crude oil refining-PX/ethylene glycol-PTA-polyester-chemical fiber”, which makes the company realize diversified development in the future. Compared with traditional fuel refineries, refinery-chemical integration has obvious advantages.

First of all, “Refining”, “Chemical” combination can maximize the use of crude oil, pure refining is not only a short production chain, but also a single product, market saturation and other shortcomings, refining and chemical integration can reduce production costs, raw material costs. Secondly, the production chain to extend down, some refineries do not have to be too constrained by the production of raw materials shortage, refining link self-production and self-consumption at the same time, but also to achieve self-production and self-use. Thirdly, the integration of refining and chemical makes the production and sales ports more flexible, and the output items are diversified. The production route can be adjusted flexibly according to the changes of profit, sales, inventory level and real-time demand of each product. Master the“Production Code”, the seller's market or the buyer's market, refining and chemical enterprise's right to speak more than one point grasp.

Before that, a number of refineries in Zhenhai, Huludao and Lihuayi had optimised their production structures and developed chemical production chains. Later, large-scale integrated refining and chemical projects such as Hengli, Zhejiang and Zhongke were put into operation. At present, domestic refineries are facing various problems such as high inventories and weak profits, and the problem of excess refining capacity is even more difficult to return to, in the future, there are only two directions for Sustainable Development: Traditional refineries will build new catalytic cracking units and subsequent cracking gasoline hydrogenation and cracking aromatics extraction units, and expand existing residual oil hydrogenation and hydrocracking units, etc. , realize from“Fuel type” refinery to“Chemical type” refinery transformation and upgrading, or one-step construction of a new refinery-chemical integration project.

02、East China led the“Refining” transformation, followed by South China, northeast

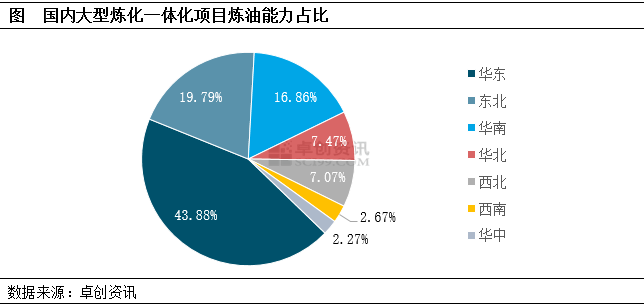

Previously, 23 large-scale integrated refining and chemical projects had been put into operation in China, with a total refining capacity of 358.9 million tons per year and a total ethylene capacity of 25.79 million tons per year. In large-scale integrated refining and chemical projects, the cumulative one-time processing capacity in east China reaches 41.38% , and this proportion will rise to 43.88% after shenghong refinery and chemical corporation starts production, as shown in the figure below. Petrochina Guangdong Petrochemical 20 million-ton-a-year refining and chemical integration project is now in its final stages of construction and is scheduled to start production in 2022, when southern China will temporarily take second place.

East China, south China and northeast China are the concentrated areas of new-type integrated refining and petrochemical enterprises. The convenient input of coastal raw materials and output of products play a decisive role in the location selection, in recent years, the enterprises of Hengli, Zhejiang Petrochemical Company and Zhongke Petrochemical Company are all scattered in these three regions. East China, especially the Yangtze River Delta, as the fastest-growing region of the domestic economy, with convenient transportation and stable consumption downstream, has undoubtedly become the first choice for newly-built refining and chemical enterprises, but this time Sheng Hong puts into production causes east China area refining and chemical pattern to accelerate the formation.

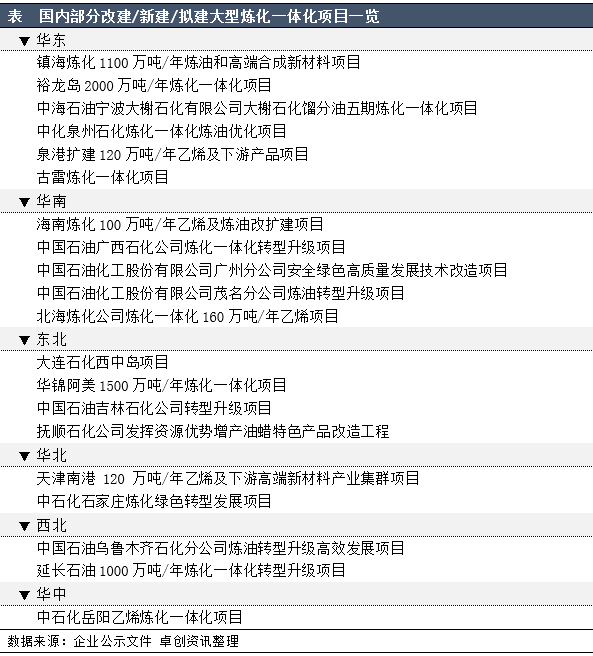

In addition to petrochina Guangdong Petrochemical, which will start production this year, there will be many large-scale refinery and chemical integration projects in China in the future, as shown in the table above. Considering the scale of investment and industrial policy, it is difficult to build new-type integrated refining and chemical enterprises such as Hengli and Zhejiang Petrochemical Company. Therefore, most refineries will naturally choose to base on the existing refining units and adjust the processing structure, to optimize the upgrading unit to achieve“Oil reduction and increase”, “Oil reduction and increase special” green transformation development, the above table is part of the existing refining based on the transformation and upgrading projects.

In terms of the number of regional planning projects, the coastal areas of east China, south China and northeast China are still the focus of large-scale refinery and petrochemical integration projects, the future leading domestic refining and chemical integration transformation pattern will not change.

03、Fine, high-end, the future direction is a new refining and chemical integration

Since March 2022, the supply of domestic refined oil products over-demand situation is relatively grim, coupled with special reasons leading to the end-of-demand contraction intensified. In terms of refined oil products, cost-driven prices are high, demand is lower than the average level in previous years, and inventory levels are high. “Reducing oil consumption and increasing oil consumption” is no longer a slogan. Some production enterprises have also put into action in the second quarter, reduce the yield of gasoline and diesel, improve the output of chemical products. However, the current refining and chemical industry is not only the surplus of basic refining products such as gasoline and diesel, but also the surplus of basic chemical products such as aromatic hydrocarbons and Olefin, but the industrial chain should continue to fine, high-end extension to the production of high value-added products, and then to the new direction of refining and chemical integration.